Audi ski ! 奥迪碳纤维滑雪板制作全过程!

By www.carbonfiber.com.cn

as a follow up to our article on the AUDI carbon ski, the designboom team visited AUDI's concept design munich

and met with german designer wolfgang egger, head of AUDI group design, and australian born, german-based designer

mark shipard, who provided us with more technical insight on the project, and explained to us the revolutionary

characteristics and technology of the AUDI carbon ski. they also pointed out the challenges of the design process -

when translating this extreme sport ski initially made for professional racers (AUDI carbon ski concept) into a premium

ski for hobby skiers (serial AUDI carbon ski, no concept), outlining and defining the differing criteria for each.

AUDI carbon ski

image © designboom

the AUDI carbon ski takes advantage of more than 20 years of partnership between the car company

and the german ski association DSV, and from AUDI motorsport's knowhow. co-developer is the

carbon competence center - the gerg group, who also produce important components for their DTM and le mans race cars.

'this first concept ski was a big challenge for us, because we wanted to make a ski with a typical AUDI approach.

we started researching together with our interior technical department, with the carbon competence

and also with providers like gerg who is producing the monocoques for racing cars, and with DSV,

the german ski federation. we tried not to design just another ski, but a really completely new and innovative

piece of sports equipment. we started from the carbon technical point of view and found that there is still no ski

produced using monocoque building principles.' - wolfgang egger

like the most sensitive parts of the race car, the body of the AUDI carbon ski concept is made completely out of carbon,

a material that is extremely robust, sturdy, supple and at the same time light.

placing the carbon sheets in the mold

the making -- exclusive image tour for designboom, courtesy AUDI

a precisely calculated number of custom-cut carbon sheets are placed in a mold.

the making -- exclusive image tour for designboom, courtesy AUDI

the process is extremely complex and requires a lot of experience, during the adaptation of the carbon cut to the form,

and while hardening in the artificial vacuum of the autoclave.

controlling the precise placement of the carbon sheets

the making -- exclusive image tour for designboom, courtesy AUDI

closing the mold before it goes into the autoclave

the making -- exclusive image tour for designboom, courtesy AUDI

the mold being placed into the autoclave vacuum

the making -- exclusive image tour for designboom, courtesy AUDI

closing the autoclave vacuum

the making -- exclusive image tour for designboom, courtesy AUDI

the surface of the ski is finished by hand

the making -- exclusive image tour for designboom, courtesy AUDI

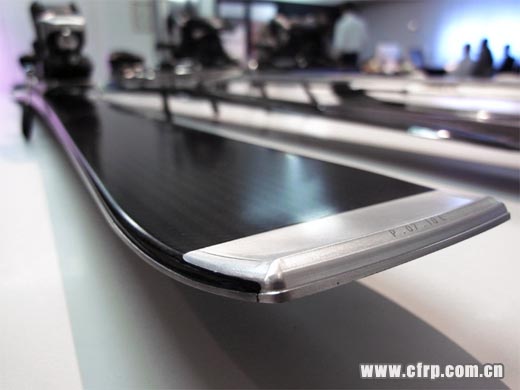

the body of the AUDI carbon ski concept is made completely of carbon, whereas the binding is dominated by aluminum.

the binding components are milled out of high tensile aluminium.

binding components are milled from aluminum blocks

the making -- exclusive image tour for designboom, courtesy AUDI

aluminum components

the making -- exclusive image tour for designboom, courtesy AUDI

aluminum shock absorber

the making -- exclusive image tour for designboom, courtesy AUDI

the making -- exclusive image tour for designboom, courtesy AUDI

the AUDI carbon ski concept is manufactured with the same standards of a race car - just as in motor sports almost

everything is handmade. the handling characteristics of the AUDI carbon ski concept are revolutionary.

the subtleness of the carbon and the flexibly mounted binding plate at the front end allow the ski to flex uniformly

along its entire length, meaning the steel edge is always perfectly in contact with the snow.

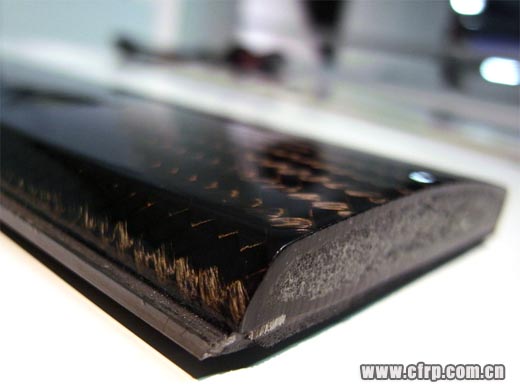

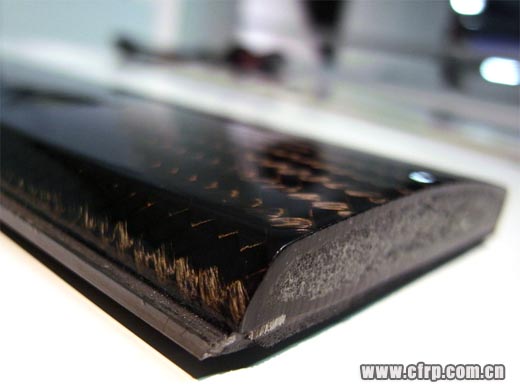

cross section detail shows the ski's monocoque structure

image © designboom

this cross section detail of the AUDI carbon ski concept shows that the closed monocoque structure.

the ski's structural composition contains no other material that has a weight carrying, functional aspect.

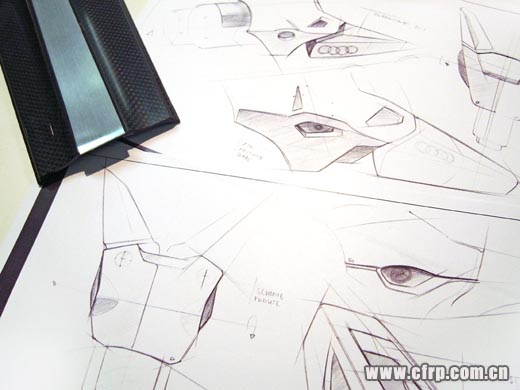

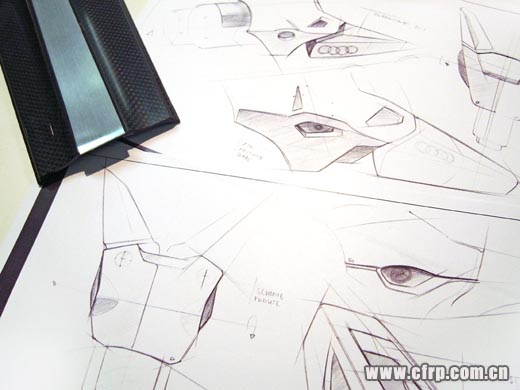

material research and sketches of the ski binding systems

image © designboom

detail of the sketches, left: first section experiment with aluminum as decoration

image © designboom

'this is just one section experiment we did in the early concept stages that deal with playing more in three dimensional forms.

we came up with a model first and after this experiment we got in contact with industry professionals.

we realized that we are dealing with a highly functional piece of hard performance sports equipment, and this was probably

not the right approach.' - mark shipard

instead of using aluminum as a decoration as in our very first design, the material is still used in the ski attractively

but with a functional purpose.

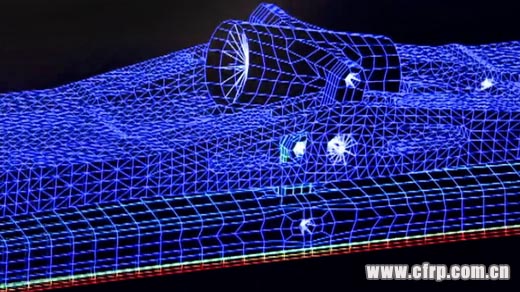

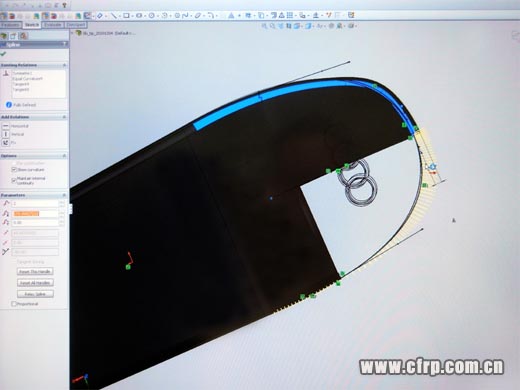

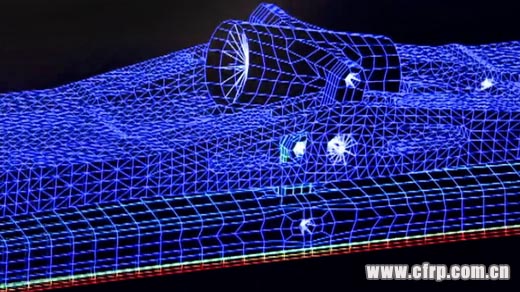

finite element analysis of the ski

the making -- exclusive image tour for designboom, courtesy AUDI

moving from concept to realization:

'the first round was done through digitalization, with the form-finding of the ski realized through a digital 3D rendering program.

this is completely new for the world of skis. first we created the digital data - the construction -

then calculated its flexibility and torque stability.' - wolfgang egger

'about 2 years ago, ski experts of the DSV tested the first prototypes, which was important because they really defined

the properties of the ski for us, and the performance levels that they wanted these professional skis to have.' - mark shipard

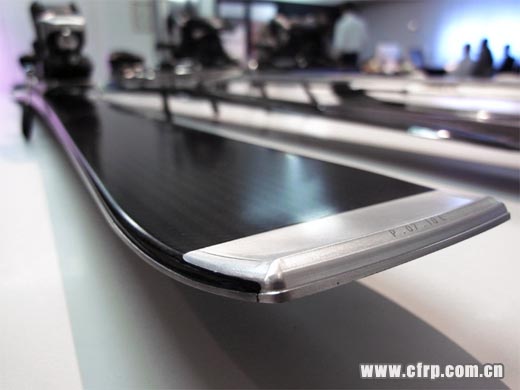

the moncoque structure

image © designboom

to optimize the stability of the structure, stiffness and flexibility were added to parts of the skis where needed.

at first the lower and the upper part of the outer layers of the monocoque ski had the same thickness.

to enhance their flexibility, the proportions were changed - the tip was made thinner and the bottom thicker.

the skis are therefore incredibly light and fast turning, with the weight of the wearer concentrated under the

ski boot and the binding system. this relates back also to AUDI's experience with cars, in which unsprung weight

is important to handling performance and agility.

first ski prototypes (left: first developments of the serial carbon ski that will go into production, right: two prototypes of the carbon concept skis)

image © designboom

the AUDI carbon ski concept is a really limited series, handmade in the autoclave (a type of oven), using carbon technology,

with details milled in aluminum. the car company wanted to enlarge the possibility of offering athletic advantages

to a larger number of their clients, as well, creating a sporty ski (racing carver) that is not just an extreme carbon ski.

now, together with the ski company HEAD they have developed a ski that targets the needs of a wider range of users

transmitting not only the design but also some carbon properties found in the original concept ski,

providing not just an extreme racing ski for professionals, but also one for hobby skiers.

image © designboom

to give value to the brand AUDI, the 4 aluminum rings of the logo are embedded within the ski tip in a more 3 dimensional way.

the name of the customer could be engraved on the panel at the back end of the ski.

aluminum panel at the back end of the ski

image © designboom

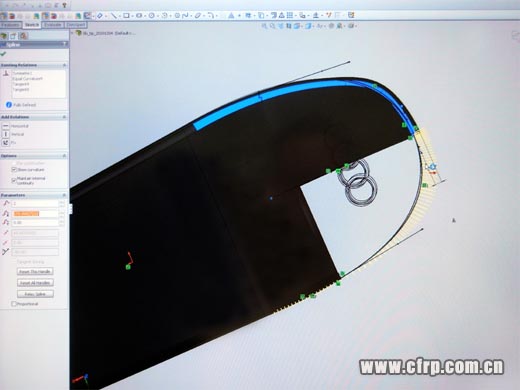

mark shipard showing the CAD model of the ski

image © designboom

due to the primary goal of developing a high-performance piece of sporting equipment, design freedom was fairly limited.

for example, for the contour of the ski, the designers had only a playing field of 0.5mm.

defining the ski's contoured shape

image © designboom

things in the ski world change very quickly, compared to other fields of industrial design, such as cars.

industrial design has to keep up with modern trends. for example, during the concept development phase of the first racing ski,

the flat tip of the ski was popular, but now it has become fashionable to have a rounded tip, so the shape is continuously changing

in order to remain current.

various studies on the contour shape of the ski tip, and the black shades of the carbon surface finishing

image © designboom

as the carbon surface is quite delicate and soft as a material, its high gloss or matte finish, it won't look good anymore,

even after just a day of wear. therefore, together with a foil specialist, AUDI is developing a new finish that will add

protective properties without compromising the aesthetic look of the carbon fibre.

'we wanted to stay very authentic to the carbon material, and did not want any kind of overdone ornamentation.

we didn't need to decorate the ski with graphics or any real 3D effects, because the material tells the story,

it is beautiful by its own,' says wolfgang egger and mark shipard.

AUDI research lab in munich

image © designboom

AUDI concept design munich

image © designboom

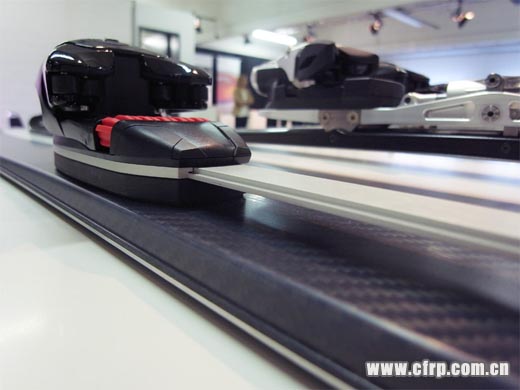

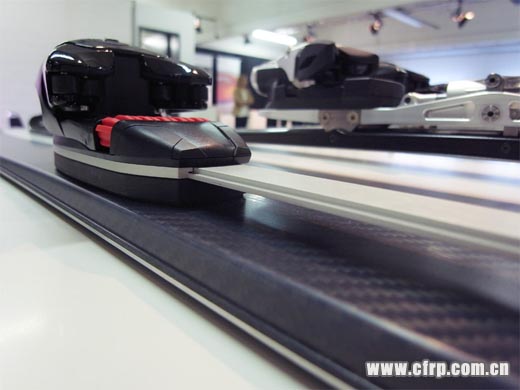

various binding systems (top: AUDI carbon ski concept, bottom: serial AUDI carbon ski)

image © designboom

the AUDI carbon ski concept has an innovative binding system:

the binding system that encompasses the whole ski boot and binding plate, is independent of the ski.

at the front of the plate system there is a pivot point. the back end features two-pivot points and the overall

module is anchored by a 4-point linkage to a hydrolic shock absorber at the centre of the plate.

therefore, when you actually bend the ski, the shock absorber moves, making the movement and flexibility

of the ski separate from the boot/binding/plate system.

another advantage of the hydrolic shock absorber is, if the ski racer does get a hit on the ski run on the ice

the ski doesn't flutter. it's quiet straight away and continues to carve.

this system was another link back to the AUDI automotive world where we have a suspension regulation for different uses,

such as a mode for the racing track, the normal street, more comfort or less comfort…

we translated this into the ski as well whereby you can change the set-up and control the hardness of the shock absorber.

for example, you can have a real racing ski that is very sporty, or there is also the option of a softer version which

provides a more relaxed and comfortable means of hitting the slopes. - wolfgang egger

the shock absorber is located in the middle of the binding system

image © designboom

the binding plate of the carbon concept ski has an integrated hydrolic absorption system that gives the ski

a previously unknown smoothness.

detail of the shock absorber

the making -- exclusive image tour for designboom, courtesy AUDI

view of the different binding systems - on the left: the first two prototypes of the AUDI carbon ski concept,

on the right: first developments of the non-racing, serial ski for average customer / hobby skier

image © designboom

each binding system is custom-made to fit one's ski boot size, length of ski, etc.

image © designboom

various explorations were made looking at developing different versions of binding systems to fit the carbon surface design.

above, the binding system front repeats the pattern of the carbon fibre, with a glossy finishing,

while the version below utilizes a transparent material in order to showcase the technical components of the unit.

image © designboom

'originally, we were only looking at the professional skier in trying to define the criteria for the skis,

however, HEAD stated that we needed to look at developing a piece of equipment that was more representative

of a broader market. in continuing our research, we realized that the hobby skier and the professional skier use skis

in very different manners. the hobby skier slides down the hill in a more 'zig zag' motion moving laterally across the slope,

different from the 'racer' who wants to go downhill at full speed. we realized that our 'race machine' had certain

characteristics that did not work for the main consumer market, therefore we had to fine-tune the properties of our

carbon concept ski for the more average customer.' - mark shipard

image © designboom

different from the AUDI carbon ski concept that is constructed using a monocoque technique, the production ski features:

- carbon fibre is used on the full cap thickness

- a very high quality wood core

- a custom-fitted binding system to customer, but reduced in complexity compared to the concept ski - there is no shock absorber

- reduced material complexity pared down to just aluminum

image © designboom

so why a ski?

a ski is obvious. it is sporty. AUDI is sporty. we have been sponsoring the world cup for many years now.

we wish to give our clients the same kind of enriched emotion derived from the daily use of their AUDI car,

by providing additional products which translate this feeling into new areas of lifestyle and living.

as a follow up to our article on the AUDI carbon ski, the designboom team visited AUDI's concept design munich

and met with german designer wolfgang egger, head of AUDI group design, and australian born, german-based designer

mark shipard, who provided us with more technical insight on the project, and explained to us the revolutionary

characteristics and technology of the AUDI carbon ski. they also pointed out the challenges of the design process -

when translating this extreme sport ski initially made for professional racers (AUDI carbon ski concept) into a premium

ski for hobby skiers (serial AUDI carbon ski, no concept), outlining and defining the differing criteria for each.

AUDI carbon ski

image © designboom

the AUDI carbon ski takes advantage of more than 20 years of partnership between the car company

and the german ski association DSV, and from AUDI motorsport's knowhow. co-developer is the

carbon competence center - the gerg group, who also produce important components for their DTM and le mans race cars.

'this first concept ski was a big challenge for us, because we wanted to make a ski with a typical AUDI approach.

we started researching together with our interior technical department, with the carbon competence

and also with providers like gerg who is producing the monocoques for racing cars, and with DSV,

the german ski federation. we tried not to design just another ski, but a really completely new and innovative

piece of sports equipment. we started from the carbon technical point of view and found that there is still no ski

produced using monocoque building principles.' - wolfgang egger

like the most sensitive parts of the race car, the body of the AUDI carbon ski concept is made completely out of carbon,

a material that is extremely robust, sturdy, supple and at the same time light.

placing the carbon sheets in the mold

the making -- exclusive image tour for designboom, courtesy AUDI

a precisely calculated number of custom-cut carbon sheets are placed in a mold.

the making -- exclusive image tour for designboom, courtesy AUDI

the process is extremely complex and requires a lot of experience, during the adaptation of the carbon cut to the form,

and while hardening in the artificial vacuum of the autoclave.

controlling the precise placement of the carbon sheets

the making -- exclusive image tour for designboom, courtesy AUDI

closing the mold before it goes into the autoclave

the making -- exclusive image tour for designboom, courtesy AUDI

the mold being placed into the autoclave vacuum

the making -- exclusive image tour for designboom, courtesy AUDI

closing the autoclave vacuum

the making -- exclusive image tour for designboom, courtesy AUDI

the surface of the ski is finished by hand

the making -- exclusive image tour for designboom, courtesy AUDI

the body of the AUDI carbon ski concept is made completely of carbon, whereas the binding is dominated by aluminum.

the binding components are milled out of high tensile aluminium.

binding components are milled from aluminum blocks

the making -- exclusive image tour for designboom, courtesy AUDI

aluminum components

the making -- exclusive image tour for designboom, courtesy AUDI

aluminum shock absorber

the making -- exclusive image tour for designboom, courtesy AUDI

the making -- exclusive image tour for designboom, courtesy AUDI

the AUDI carbon ski concept is manufactured with the same standards of a race car - just as in motor sports almost

everything is handmade. the handling characteristics of the AUDI carbon ski concept are revolutionary.

the subtleness of the carbon and the flexibly mounted binding plate at the front end allow the ski to flex uniformly

along its entire length, meaning the steel edge is always perfectly in contact with the snow.

cross section detail shows the ski's monocoque structure

image © designboom

this cross section detail of the AUDI carbon ski concept shows that the closed monocoque structure.

the ski's structural composition contains no other material that has a weight carrying, functional aspect.

material research and sketches of the ski binding systems

image © designboom

detail of the sketches, left: first section experiment with aluminum as decoration

image © designboom

'this is just one section experiment we did in the early concept stages that deal with playing more in three dimensional forms.

we came up with a model first and after this experiment we got in contact with industry professionals.

we realized that we are dealing with a highly functional piece of hard performance sports equipment, and this was probably

not the right approach.' - mark shipard

instead of using aluminum as a decoration as in our very first design, the material is still used in the ski attractively

but with a functional purpose.

finite element analysis of the ski

the making -- exclusive image tour for designboom, courtesy AUDI

moving from concept to realization:

'the first round was done through digitalization, with the form-finding of the ski realized through a digital 3D rendering program.

this is completely new for the world of skis. first we created the digital data - the construction -

then calculated its flexibility and torque stability.' - wolfgang egger

'about 2 years ago, ski experts of the DSV tested the first prototypes, which was important because they really defined

the properties of the ski for us, and the performance levels that they wanted these professional skis to have.' - mark shipard

the moncoque structure

image © designboom

to optimize the stability of the structure, stiffness and flexibility were added to parts of the skis where needed.

at first the lower and the upper part of the outer layers of the monocoque ski had the same thickness.

to enhance their flexibility, the proportions were changed - the tip was made thinner and the bottom thicker.

the skis are therefore incredibly light and fast turning, with the weight of the wearer concentrated under the

ski boot and the binding system. this relates back also to AUDI's experience with cars, in which unsprung weight

is important to handling performance and agility.

first ski prototypes (left: first developments of the serial carbon ski that will go into production, right: two prototypes of the carbon concept skis)

image © designboom

the AUDI carbon ski concept is a really limited series, handmade in the autoclave (a type of oven), using carbon technology,

with details milled in aluminum. the car company wanted to enlarge the possibility of offering athletic advantages

to a larger number of their clients, as well, creating a sporty ski (racing carver) that is not just an extreme carbon ski.

now, together with the ski company HEAD they have developed a ski that targets the needs of a wider range of users

transmitting not only the design but also some carbon properties found in the original concept ski,

providing not just an extreme racing ski for professionals, but also one for hobby skiers.

image © designboom

to give value to the brand AUDI, the 4 aluminum rings of the logo are embedded within the ski tip in a more 3 dimensional way.

the name of the customer could be engraved on the panel at the back end of the ski.

aluminum panel at the back end of the ski

image © designboom

mark shipard showing the CAD model of the ski

image © designboom

due to the primary goal of developing a high-performance piece of sporting equipment, design freedom was fairly limited.

for example, for the contour of the ski, the designers had only a playing field of 0.5mm.

defining the ski's contoured shape

image © designboom

things in the ski world change very quickly, compared to other fields of industrial design, such as cars.

industrial design has to keep up with modern trends. for example, during the concept development phase of the first racing ski,

the flat tip of the ski was popular, but now it has become fashionable to have a rounded tip, so the shape is continuously changing

in order to remain current.

various studies on the contour shape of the ski tip, and the black shades of the carbon surface finishing

image © designboom

as the carbon surface is quite delicate and soft as a material, its high gloss or matte finish, it won't look good anymore,

even after just a day of wear. therefore, together with a foil specialist, AUDI is developing a new finish that will add

protective properties without compromising the aesthetic look of the carbon fibre.

'we wanted to stay very authentic to the carbon material, and did not want any kind of overdone ornamentation.

we didn't need to decorate the ski with graphics or any real 3D effects, because the material tells the story,

it is beautiful by its own,' says wolfgang egger and mark shipard.

AUDI research lab in munich

image © designboom

AUDI concept design munich

image © designboom

various binding systems (top: AUDI carbon ski concept, bottom: serial AUDI carbon ski)

image © designboom

the AUDI carbon ski concept has an innovative binding system:

the binding system that encompasses the whole ski boot and binding plate, is independent of the ski.

at the front of the plate system there is a pivot point. the back end features two-pivot points and the overall

module is anchored by a 4-point linkage to a hydrolic shock absorber at the centre of the plate.

therefore, when you actually bend the ski, the shock absorber moves, making the movement and flexibility

of the ski separate from the boot/binding/plate system.

another advantage of the hydrolic shock absorber is, if the ski racer does get a hit on the ski run on the ice

the ski doesn't flutter. it's quiet straight away and continues to carve.

this system was another link back to the AUDI automotive world where we have a suspension regulation for different uses,

such as a mode for the racing track, the normal street, more comfort or less comfort…

we translated this into the ski as well whereby you can change the set-up and control the hardness of the shock absorber.

for example, you can have a real racing ski that is very sporty, or there is also the option of a softer version which

provides a more relaxed and comfortable means of hitting the slopes. - wolfgang egger

the shock absorber is located in the middle of the binding system

image © designboom

the binding plate of the carbon concept ski has an integrated hydrolic absorption system that gives the ski

a previously unknown smoothness.

detail of the shock absorber

the making -- exclusive image tour for designboom, courtesy AUDI

view of the different binding systems - on the left: the first two prototypes of the AUDI carbon ski concept,

on the right: first developments of the non-racing, serial ski for average customer / hobby skier

image © designboom

each binding system is custom-made to fit one's ski boot size, length of ski, etc.

image © designboom

various explorations were made looking at developing different versions of binding systems to fit the carbon surface design.

above, the binding system front repeats the pattern of the carbon fibre, with a glossy finishing,

while the version below utilizes a transparent material in order to showcase the technical components of the unit.

image © designboom

'originally, we were only looking at the professional skier in trying to define the criteria for the skis,

however, HEAD stated that we needed to look at developing a piece of equipment that was more representative

of a broader market. in continuing our research, we realized that the hobby skier and the professional skier use skis

in very different manners. the hobby skier slides down the hill in a more 'zig zag' motion moving laterally across the slope,

different from the 'racer' who wants to go downhill at full speed. we realized that our 'race machine' had certain

characteristics that did not work for the main consumer market, therefore we had to fine-tune the properties of our

carbon concept ski for the more average customer.' - mark shipard

image © designboom

different from the AUDI carbon ski concept that is constructed using a monocoque technique, the production ski features:

- carbon fibre is used on the full cap thickness

- a very high quality wood core

- a custom-fitted binding system to customer, but reduced in complexity compared to the concept ski - there is no shock absorber

- reduced material complexity pared down to just aluminum

image © designboom

so why a ski?

a ski is obvious. it is sporty. AUDI is sporty. we have been sponsoring the world cup for many years now.

we wish to give our clients the same kind of enriched emotion derived from the daily use of their AUDI car,

by providing additional products which translate this feeling into new areas of lifestyle and living.