Tooling for composites: Evolutionary trajectory 复合材料模具演化轨迹(英文版)

By www.carbonfiber.com.cn

A carbon fiber aerospace tool is machined in a Janicki Industries (Sedro-Wooley, Wash.) mill. The company has developed composite systems for producing tools via infusion and out-of-autoclave methods. Source: Janicki Industries

华盛顿的Sedro-Wooley公司通过液牙和热压釜成型方法开发的复合材料生产工具。

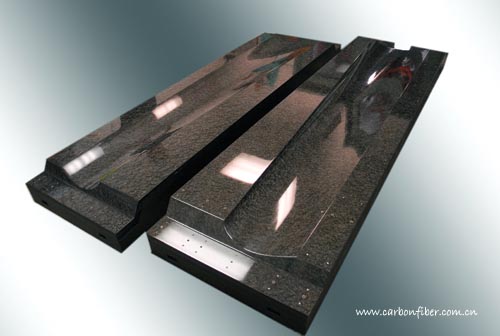

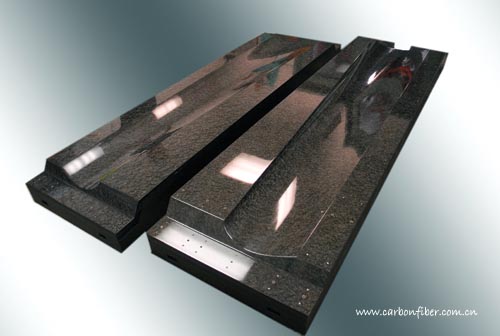

A finished CFOAM composite tool for the Shadow 200 UAV wingskin tool set manufactured by Touchstone Research Laboratory (Tridelphia, W.Va.). The company has developed self-heated carbon foam tools that it calls Electrically Heated Tooling (EHT). Source: Touchstone Research Laboratory

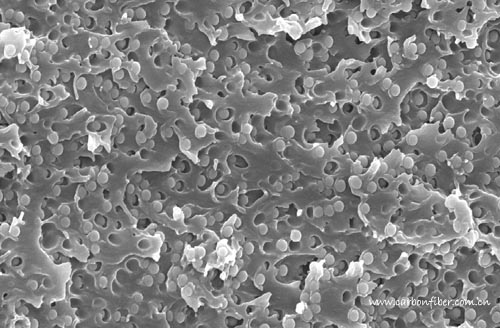

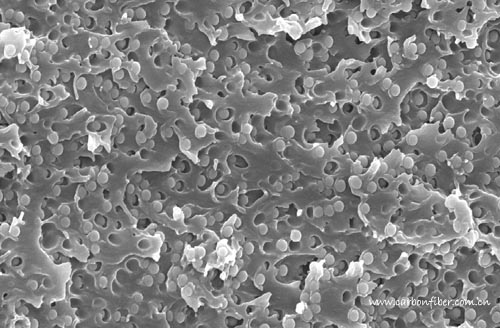

3M (St. Paul, Minn.) now provides resins and tooling prepregs that are nano-enhanced with silica particles for improved properties, including increased fracture toughness that reduces composite microcracking. This photo is a micrograph image of fractured cured resin that contains the spherical silica. Source: 3M

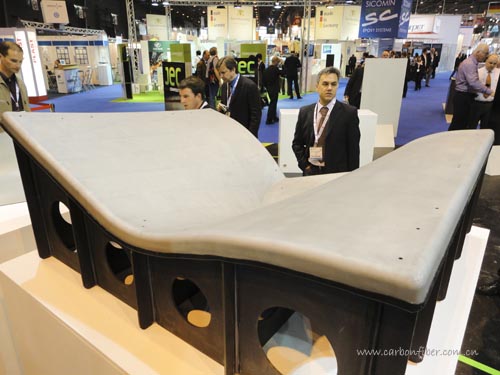

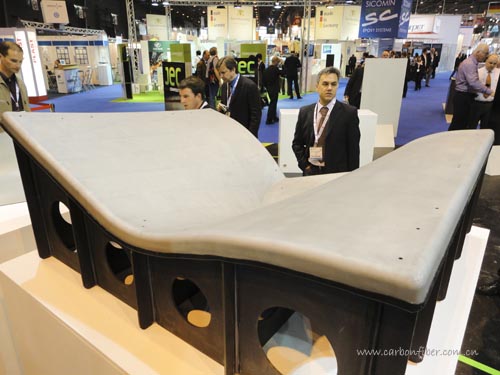

A Carbovar tool, on display at the recent 2011 JEC Composites Show, combines a nano-structured metallic coating by Integran Technologies (Toronto, Ontario, Canada) over a carbon prepreg composite tool from Advanced Composites Group (Tulsa, Okla.). The result is a low-thermal-mass, lightweight tool with the surface durability of metal tooling. Source: HPC: Photo: Jeff Sloan

This complex carbon fiber part was produced in a multi-piece RTM mold designed and built by Compose (Bellignat, France), as part of a demonstrator project in collaboration with Group Latecoere in France. Source: Compose

Sand molds are robotically produced direct from customer CAD data at Waukesha Foundry (Waukesha, Wis.), eliminating the need for foundry patterns, in the production of cast Invar tool components. Source: Waukesha Founfry

Vacuum-tight, repairable nickel vapor deposition (NVD) tools created by Weber Manufacturing Technologies (Midland, Ontario, Canada) for the Boeing 787 vertical stabilizer leading edge. NVD tools are capable of long production life at high temperatures. Source: Weber Manufacturing Technologies

This tool, designed by Radius Engineering (Salt lake City, Utah) for Same-Qualified Resin Transfer Molding (SQRTM) in a project with partner COEXPAIR, was used to produce a complex main landing gear bay part with integral ribs and stringers. Source: Radius Engineering

Article From: High-Performance Composites July2011, Sara Black

ShareThis

www.carbonfiber.com.cn

Posted on: 7/1/2011

Tooling is the vital but often underappreciated silent partner behind every well-designed composite part. It also can be a very costly aspect of that part’s production. The manager for a Tier 1 aerospace facility recently revealed that the tool inventory in the plant cost more than the building and all its production equipment combined! Given that level of investment, molders want to get the most out of their tooling dollars. Toward that end, HPC compiled the following review with a focus on out-of-autoclave (OOA) approaches and other evolving technologies for thermoset composites.

Self-heating tools save time

A tooling material that has attracted considerable attention since its commercial introduction seven years ago is carbon foam. This low-density, machinable material has a low coefficient of thermal expansion (CTE) compatible with carbon composites (see “Carbon/BMI and carbon foam form Invar alternative,” under "Editor's Picks"). Now, engineers at Touchstone Research Laboratory Ltd. (Triadelphia, W.V.) have introduced Electrically Heated Tooling (EHT), a self-heated foam tool for OOA processing.

Touchstone’s Jesse Blacker explains that its CFOAM is produced from powdered bituminous coal, which is pressed into tray molds and processed under high heat and pressure in an autoclave. Foam panels are bonded together to form a near net-shape billet, which is machined to the desired shape. A tool face is formed by applying a composite material, such as Hexcel’s (Stamford, Conn.) HexTool mat material. After cure of the tool face, the CFOAM tool is CNC-machined to the final profile, wet sanded, sealed and prepared for part production.

EHT tooling incorporates a constant cross-section, resistively heated foam heating element (identical to the CFOAM used in the tool) just beneath the tool face. A graphite electrode is connected to the element to provide electricity, and the element itself is isolated from the rest of the tool mass, explains Blacker. “In this way, resistive heating occurs only beneath the tool face, making the tool more energy efficient, and the underlying foam substrate that’s not heated acts to thermally insulate the face and minimize heat losses.”

The electrical isolation of the heating element is tricky and required experimentation, he explains. Because CFOAM tools are built up from panels that are adhesively bonded together, a silver-filled conductive adhesive is needed for the panels that make up the heating element to ensure uniform current flow. The heating element is isolated by barrier layers — film adhesive, elastomeric rubber, quartz fiber or some combination of the three. “The carbon fibers used in the tool face are more conductive than the carbon foam,” Blacker points out. If fiber and foam make contact, a short circuit would result in uneven heating. “By isolating the heating element, we can create consistent tool surface heating.”

Test results show that the tool delivers mechanical properties equivalent to standard autoclave-cured laminates for both a flat and a complex tool shape.

At the recent JEC Composites Show 2011 in Paris, Techni Modul Engineering (Coudes, France) attracted interest with a self-heated tool design for high-rate production. Company CEO Serge Luquain describes the new concept, a JEC Innovation Award finalist in the Equipment category, as a “tool with a thin skin, self-heated and cooled, for curing either in or out of the autoclave.” Although few tool details were on offer, Luquain revealed that the fluid circulation system can accept oil, water or metal-based fluids and that the maximum fluid temperature is approximately 400°C/752°F. The tool skin can be made from metal or composite.

“In most cases, self-heating tools are very thick and massive,” he adds. “Ours is very thin and, thus, can heat more quickly, using less energy.” Although autoclave tools normally ramp up at 3°C to 4°C (37°F to 39°F) per minute, the self-heated tool heats at a rate of 20°C to 30°C (68°F to 86°F) per minute.

Luquain illustrates another advantage, weight savings, by contrasting the Techni Modul tool with one made of machined billets of Invar (a 36 percent nickel/steel alloy): “The Invar tool is 22 [metric] tonnes [(48,502 lb)], compared to ours at only 5 [metric] tonnes [(11,023 lb)], which is capable of making the same part more efficiently.”

The initial target market will be OOA infusion molding of large parts. Pending licensing agreements, the commercialized tool concept could soon be available in North America through a U.S. casting company, says Techni Modul. The company also is exploring resin transfer molding (RTM) tool concepts using thick 3-D stitched preforms in partnership with a Japan-based firm.

Since its debut a decade ago, Surface Generation Ltd.’s (Oakham, Rutland, U.K.) reconfigurable pin tooling (RPT) approach for OOA applications has undergone significant development, says company CEO Ben Halford. (For RPT background, see “Tooling and toolmaking innivations continue," under Editor's Picks," at top right”). “We’re now offering a fully integrated system that includes the tool, heating and cooling system, data logging, control and cure-management software, all developed in-house.” This “intelligent molding environment” works on the principle that each of the moveable pins making up the tool can be heated and cooled very accurately and rapidly. The pin temperature can rise at a rate of up to 200°C/392°F per minute to a maximum of 700°C/1292°F. The mold temperature and the temperature change rate also can be varied in localized zones. Further, the mold heating/control system can be retrofitted to a conventional tool. On an existing autoclave facesheet tool, it can accelerate heating inside the autoclave, for a cure cycle up to 20 times faster than can be achieved with the autoclave alone, claims Halford. Although the system demands considerable electrical power, energy consumption is reportedly less than 5 percent of that required by an autoclave. “And, we can put the heated tool into an autoclave and use the autoclave only to apply pressure, which creates massive energy and cycle time reductions,” adds Halford. And the company is looking to apply the temperature-control system to automated fiber placement and tape laying processes.

“Small” changes, big improvements

Nanotechnology-enhanced improvements to tooling are having a significant impact on tool durability. Featured in HPC during its development phase (see “New metal coating to optimize composite tooling,” under "Editor's Picks"), a nanostructured nickel/iron coating with a low CTE, developed by Integran Technologies Inc. (Toronto, Ontario, Canada), has been combined with carbon composite tooling prepregs from Advanced Composites Group Ltd. (ACG, Heanor, Derbyshire, U.K.) to create Carbovar. This tool concept combines the low weight and low thermal mass of a composite tool with the surface durability and hardness of a metal tool at a considerable savings, compared to all-metal tools. The winner of this year’s JEC Innovation Award in the Equipment category was a Carbovar demonstrator tool for an Airbus (Toulouse, France) A320 wing-to-fuselage fillet fairing. Reportedly, the five-year project has overcome issues that include optimizing the bond between the nanocrystalline coating and the carbon fiber tool face under thermal cycling, and achieving consistent coating thickness around complex tool face geometries. The next hurdle? Increase the tool size, currently limited to the dimensions of the metallic coating deposition tank.

Elsewhere, 3M Advanced Composites (St. Paul, Minn.) recently introduced a line of nano-enhanced epoxy resins and a line of tooling prepregs made from them, trademarked 3M Prepreg. The epoxy contains nanoscale spherical silica particles (see photo at right) at loadings of 30 to 40 percent, says Jim Nelson, 3M’s senior product development specialist: “The nanoparticles act to significantly improve resin hardness for improved scratch resistance, and they increase fracture toughness and compression strength of the composite as well, without compromising other important properties.” Tests by 3M reportedly show a 68 percent increase in Barcol hardness (79, up from 38); a 33 percent decrease in CTE (27 µm/m/°C, compared to 40 µm/m/°C in a standard epoxy); and a 24 percent decrease in moisture uptake (to only 2.7 percent).

Carbon/epoxy composites have high specific strength and stiffness but often are limited in compression strength, which is heavily influenced by the shear modulus of the matrix resin. “A higher-modulus matrix resin will support the fibers to reduce or delay microbuckling,” says Nelson, “but typically, most epoxy toughening strategies that increase matrix fracture-resistance tend to reduce the modulus.” According to the company, 3M’s spherical silica particles are extremely small (about 100 nm in diameter). Therefore, they remain homogenously distributed in the matrix, unaffected by the inadvertent filtration that could occur with larger particulate fillers as they flow through the reinforcement during wetout. In the finished part, the nanofiller helps dissipate fracture energy through viscous deformation of the matrix and increased surface roughness of the fracture plane. Says Janet Kirkman, 3M’s commercialization marketing manager, “Adding the nanosilica improves modulus and toughness while preserving glass transition temperature.”

Other benefits are said to include less moisture absorption than typical epoxies, less shrinkage during cure, a low CTE compatible with carbon parts, and decreased exotherm compared to traditional tooling prepregs. The latter makes thicker tools possible, and that means tooling laminates can be cured more quickly, saving production time.

Targeted mainly to OOA processing, the new prepregs are available in three cure temperatures: 120°F/48°C, 140°F/60°C and 180°/82°C. Although the silica at fairly high loading slightly increases the density of the prepregs, Nelson points out that overall their properties are superior to those of typical tooling prepregs. Therefore, he says, “you can work with the tool design a bit to take out some fiber and reduce the weight, if weight is a concern.” The materials are currently being tested by customers, in one case as long-term production tooling. “We’re investigating, right now, tool performance and durability after 500 cycles,” concludes Nelson.

Toolmakers refine methods, reduce costs

Tooling materials aren’t the only focus for evolution. Tool providers have led the way in combining materials and toolmaking techniques to reduce tool cost and extend the useful life of molds.

Janicki Industries (Sedro-Woolley, Wash.) offers both metal and composite tooling. The latter is offered in three classes: short two-cycle tools, intermediate 50-cycle tools and long-cycle tooling. Many are made with Janicki’s composite tooling systems, termed JAA and JRBOA, for producing tools via infusion and OOA methods. Very large tools can be fabricated using the company’s 100-ft/31m long oven, far beyond the lengths allowed by autoclaves. With the company’s gantry-mounted 5-axis machining center, which features a 100-ft bed, the cured composite tooling is machined to high tolerance. Supported by the company’s new in-house research lab, Janicki has the capability to simulate tool longevity, using thermal mass analysis, differential scanning calorimetry and heat deflection tests for customers and is working closely with resin companies to test OOA systems, adds W. Brian Holmes, Janicki’s VP, aerospace.

OOA processes, such as RTM and its variants, are maturing thanks to recent development efforts by toolmakers with expertise in metal tooling for resin infusion of complex parts. Late in 2009, for example, North Coast Tool and Mold (Cleveland, Ohio) submitted a bid for additional RTM rate tools on a very large production job. While the customer had been producing parts with tools in heated platen presses, North Coast’s president, Rich Petrovich, says his company proposed out-of-press tools, integrally heated, for faster throughput and lower energy consumption. “Our client and the end-user had to be convinced, and it was not easy,” he notes. “Our industry is justifiably concerned about using a different technology when a lot is at stake. But in the end we were able to prove that the approach worked.”

The tool design, for a part roughly 21 inches wide, 52 inches long and with a depth of 19 inches (0.5m by 1.33m by 0.49m), was produced with Invar and included heating and cooling channels, uniformly distant from the tool face. Considerable energy was saved because only the tool was heated, not large press platens. And the dedicated press for each production tool was eliminated. Because the tool heating was faster, the cycle time was reduced for more efficient throughput. The smaller tool footprint also was more ergonomic, and less handling equipment was required during the cure cycles. Adds Petrovich, “With ... projects requiring larger production quantities, more emphasis needs to be put on lower cost, lighter weight, easier-to-use tooling that doesn’t require the unnecessary expense of dedicated presses or autoclaves while saving significant energy. This translates into lower total cost for composite parts.”

Radius Engineering’s (Salt Lake City, Utah) president, Dimitrije Milovich, maintains that “high-quality, net-shaped composite parts can be produced with low void content and excellent dimensional control, with well-designed, two-part steel or aluminum tools.”

Part size, he explains, is the key when designing RTM tools. Self-clamped matched molds are acceptable for smaller parts, less than 1.5m/5 ft in length, to keep recurring labor costs lower — it takes a lot of time to fasten and unfasten all those bolts. Larger parts require considerable tool mass to react he internal resin pressure, he explains: “You may need as much as 15 tons of steel, and tool heating will be much slower and handling more difficult with a big, self-clamped tool. We generally recommend a press-clamped tool.” Although some toolmakers prefer Invar for its durability and low CTE, Milovich claims that his company has proven, in a production environment, that differences in CTE between carbon composites and aluminum can be compensated for in tool design, even in large sizes, and that hard anodizing improves aluminum’s surface durability and thermal behavior over steel and Invar, resulting in faster processes and, therefore, lower energy costs.

The company has commercialized a process called Same-Qualified Resin Transfer Molding (SQRTM), in which program-qualified, toughened prepreg is layed up in an RTM matched mold, a vacuum is drawn, air is evacuated from the layup and a small quantity of the same resin used in the prepreg is injected into the tool. This creates hydrostatic pressure on the prepreg layup that keeps volatiles and water vapor in solution and prevents void formation (see “SQRTM enables net-shape parts," under Editor's Picks”). The process reportedly yields autoclave-quality parts outside the autoclave, in a faster cure cycle. The company, in collaboration with its partner COEXPAIR (Spy, Belgium), recently designed a SQRTM tool for SABCA Limburg’s (Lummen, Belgium) complex main landing gear bay demonstrator, with integral ribs and stringers. Despite the part’s complexity, SQRTM produced a lighter, more highly integrated part faster, with fewer fasteners than an autoclaved alternative.

Another closed-molding innovator, Compose (Bellignat, France), has developed an “autonomous” self-heated RTM tool for a one-piece composite aircraft passenger door by Group Latecoere (Toulouse, France). The award-winning multipiece tool combines Invar, steel and aluminum, and accepts a complex, 3-D stitched carbon preform. Prospect Mold (Cuyahoga Falls, Ohio) specializes in multipiece RTM molds of complex geometry for highly unitized structures. Tools are designed with Unigraphics (Siemens PLM Software Inc., Plano, Texas) and CATIA (Dassault Systèmes, Lowell, Mass.), says vice-president of sales and marketing Jeff Glick. And Westminster Solutions Inc. (Plainfield, Conn.) has developed a thermal management system for RTM molding that uses circulating water rather than oil. This enables cycle time reductions of as much as 35 percent, especially during ramp-down, resulting in overall lower system cost.

Hampson Tooling Solutions, consisting of Coast Composites Inc. (Santa Ana and Irvine, Calif.), Global Tooling Systems and Odyssey Industries (Detroit, Mich.) part of U.K.-based Hampson Industries Plc, is a major supplier of metal tooling used in composites fabrication, with a long aerospace history, says Hampson CEO Paul Walsh. But, he explains, as composites have migrated into critical airframe structures over the past decade, with ever larger parts, “tooling has never before been made at the massive scale now required.”

The company has produced the tooling for more than half of the Airbus A350’s outer surface, including the forward fuselage, wings, center wingbox, and sections of mid- and aft-fuselage as well as some stringer and nacelle tools. Invar was the choice for the cure tools, with steel or aluminum selected for trim tools and other tool types. But the company also produces large composite tools. “Starting with part models, we designed and built the A350 tools from, the entire turnkey operation, which was a departure for Airbus. In the past, many of the tools were sourced locally in Europe.”

Coast is “patternless”: The digital model-based tool design is transferred directly to the shop, where Invar sheets are welded or materials are machined to form the tool face. Equipment at Coast includes large 5-axis CNC machines from Henri Liné (Granby, Quebec, Canada) and Handtmann CNC Technologies (East Dundee, Ill.) with twin Siemens Sinumerik 840D numerical controls. To ensure tight tolerances, says Walsh, Coast developed its own system to compensate for real-time temperature changes on the tool materials during machining. Accuracies reportedly can be maintained within ±0.010 inches (±0.254 mm) on tool structures up to 60 ft/6.8m long.

Waukesha Foundry Inc. (Waukesha, Wis.) has produced cast Invar custom tool components for nearly two decades, for customers that include The Boeing Co. (Chicago, Ill.), Lockheed Martin (Bethesda, Md.) and Airbus, and the company has improved its manufacturing processes to streamline production and bring down the cost of an Invar tool face. Invar is still the star in the metal tools arena due to its very low CTE, nearly the same as that of carbon/epoxy. Because an Invar mold expands and shrinks at the same rate as the composite material, no stresses are imparted to the molded composite part, says David Nelson, Waukesha’s market segment manager.

Nelson and Waukesha president Ken Kurek confirm that in many cases casting a tool skin is a better alternative to traditional bump forming and welding. Says Kurek, “With a press-shaped metal tool face that’s welded, there is always the potential for leak paths. Casting can create complex tool geometry in one piece, with no welding required.” Although metal castings also can have porosity, due to trapped gases or turbulence in the metal during the casting process, Nelson claims Waukesha’s expertise and long experience in Invar casting allows “relatively thin sheets that are vacuum tight.”

Waukesha has successfully eliminated the need for foundry patterns and the considerable cost they represent, says Nelson, by simply taking the customer-supplied CAD data for the tool face and converting it directly to the machine code that drives the company’s robotic machining centers, which produce the sand molds for the castings. Resin-bonded sand is first mixed — “There’s an entire science involved with foundry sand,” says Kurek — and dropped into a “flask” or box to contain the material while it hardens. Then the sand block is machined and trimmed to form the “cope” or upper half is mated with the “drag,” or lower half, of the mold. Molten Invar is poured into the sand mold to form the tool face or particular component. After extensive nondestructive testing, the casting is typically shipped to a tool shop for machining and assembly with a backing structure and the other hardware necessary for production.

“Our specialty is making thin cast tool facesheets,” says Nelson. “While Invar is expensive, we can make the face with less material than machining from billets, so it’s a more economical method, particularly for tools with a complex geometry.” Waukesha has supplied smaller portions of a larger tool, for instance, where a complex-shaped Invar portion is mated with and welded to a larger tool. Despite the OOA trend, Nelson and Kurek say there is always a need for robust metal molds. “Metallic tools last a lifetime,” concludes Kurek.

Tom Schmitz of Weber Manufacturing Technologies Inc. (Midland, Ontario, Canada) agrees. Weber is well known for its nickel vapor deposition (NVD) tools, made by combining ground nickel powder with carbon monoxide gas in a reactor. The resulting vapor is condensed into a liquid and pumped to a deposition chamber, where it is reheated and vaporized. Solid nickel then deposits at a thickness of 0.010 inch/0.254 mm per hour onto a CNC-machined aluminum mandrel, and forms a thin uniform shell tool face. The thickness of the nickel shell is controlled by the length of time in the chamber and can be any thickness specified, regardless of mold size. Although the CTE of NVD tools is about the same as tool steel, its thermal conductivity is three times higher for faster thermal cycling. The company produces tools for autoclave and OOA processes and can integrate conformal mold-face heating and cooling into a tool. “Out-of-autoclave hasn’t been embraced yet by aerospace manufacturers,“ Schmitz notes, “but we’re working on tools for automotive suppliers who are moving in that direction” (see, for example, “Gurit CBS for the Aston Maritn DBS,” under "Editor's Picks").

Newly approved as a Boeing vendor, Weber recently produced six NVD autoclave bonding tools for the 787 Dreamliner’s vertical tail fin leading edge. Shell thickness was about 0.20 inch/5 mm. Length ranged from 80 inches/2.03m to 130 inches/3.33m long and depth was 12 inches/0.3m to 24 inches/0.62m, with a U-shaped cross section. The backup structure is a welded steel frame.

New options for trapped tooling

Trapped tools, those used to provide support on the inside walls of hollow parts, often present part designers with the problem of postcure tool removal. Tool removal can be difficult, but leaving the tool in place can compromise part weight and function. Here, HPC reports on several new approaches to this demolding dilemma.

Smart Tooling, a trademarked product of Spintech Ventures LLC (Xenia, Ohio), uses fiber-reinforced shape memory polymers (SMPs) as a trapped tooling solution for aerospace applications and other markets. The company’s reusable Smart Mandrels and SMP Bladders are less-expensive alternatives to silicone bladders and washout materials as well as multipiece tooling that must be disassembled for removal. Further, they are quicker and easier to use, claims chief technology officer Ernie Havens. “They are also amenable to automation and faster layup processes for lower manufacturing cost,” he adds.

A Smart Mandrels blank (fiber-reinforced SMP formed into hollow tubing) is placed into a two-part mandrel mold and heated to soften the blank; when softened, the mandrel is pushed against the mold contours with air pressure. After it is cooled, the SMP becomes rigid and maintains the molded shape. The rigid mandrel is then coated with a mold release and used for layup of a composite part; the part, during cure, is heated to 250°F/121°C, which is below the mandrel’s transition temperature, says Havens. Then, the mandrel is reheated to above its softening temperature (more than 250°F). It resumes its original tube shape and can be extracted from the cured part. The company claims that layup time is significantly reduced when compared to other trapped tooling approaches, which require time to fabricate or wash out. Additionally, disposal of washout residue is not an issue.

The company’s SMP Bladder works similarly but offers compatibility with cure temperatures up to 350°F/176°C. The difference is that the layup is placed into a female tool matched to the outer mold line during cure. Air pressure is applied to the SMP Bladder for consolidation purposes. As the part heats up during cure, the SMP Bladder transitions from a rigid tool to a soft elastic tool, allowing the press operator to use air pressure to further consolidate the layup prior to cure. When the cure cycle is complete, the air pressure is vented and the SMP Bladder shrinks to its original hose-like shape and can be pulled out of the cured part like any other inflatable bladder while the composite remains in the female mold cavity to cool before final demolding.

Washout mandrels have been a traditional choice, but Advanced Ceramics Mfg. (Tucson, Ariz.) says it has taken them to the next level, with its RapidCore mandrel manufacturing process, which eliminates mandrel tooling. A mandrel is “printed” directly from the customer’s CAD file, using an additive manufacturing process (see “The rise of rapid manufacturing,” under "Editor's Picks," at top right) and material system, based on the company’s water-soluble materials. When it is complete, the mandrel is coated with a fluoropolymer tape to protect it from water and is then used for part layup. Mandrels can be created in a fraction of the time required for plaster or eutectic salts and possess a compressive strength greater than 100 psi/6.89 bar and a thermal degradation temperature of approximately 350°F/177°C, which is consistent with industry-standard autoclave parameters. After part cure, the RapidCore material is simply washed out with water.

Nevada Composites (Dayton, Nevada) provides warm-water washout mandrels for trapped tooling and traditional single-sided tools, using a moderately priced rapid tooling material, trademarked Green-Aero, based on ceramic microspheres mixed with water-soluble inorganic binders. Lightweight tools are produced via a vacuum molding process in a few days, a process that is speeded by making molds for the mandrels and masters for single-sided tools using an additive manufacturing process, fused deposition modeling. The mandrels and tools have a low CTE and low thermal mass, says company CEO Linda Clements. “By tailoring the tooling material by, for example, varying the particle type and amount or the binder quantity and additives, we can adjust washout properties, improve machinability and mechanical properties, and tailor thermal properties.” Green-Aero is reportedly environmentally benign.

A carbon fiber aerospace tool is machined in a Janicki Industries (Sedro-Wooley, Wash.) mill. The company has developed composite systems for producing tools via infusion and out-of-autoclave methods. Source: Janicki Industries

华盛顿的Sedro-Wooley公司通过液牙和热压釜成型方法开发的复合材料生产工具。

A finished CFOAM composite tool for the Shadow 200 UAV wingskin tool set manufactured by Touchstone Research Laboratory (Tridelphia, W.Va.). The company has developed self-heated carbon foam tools that it calls Electrically Heated Tooling (EHT). Source: Touchstone Research Laboratory

3M (St. Paul, Minn.) now provides resins and tooling prepregs that are nano-enhanced with silica particles for improved properties, including increased fracture toughness that reduces composite microcracking. This photo is a micrograph image of fractured cured resin that contains the spherical silica. Source: 3M

A Carbovar tool, on display at the recent 2011 JEC Composites Show, combines a nano-structured metallic coating by Integran Technologies (Toronto, Ontario, Canada) over a carbon prepreg composite tool from Advanced Composites Group (Tulsa, Okla.). The result is a low-thermal-mass, lightweight tool with the surface durability of metal tooling. Source: HPC: Photo: Jeff Sloan

This complex carbon fiber part was produced in a multi-piece RTM mold designed and built by Compose (Bellignat, France), as part of a demonstrator project in collaboration with Group Latecoere in France. Source: Compose

Sand molds are robotically produced direct from customer CAD data at Waukesha Foundry (Waukesha, Wis.), eliminating the need for foundry patterns, in the production of cast Invar tool components. Source: Waukesha Founfry

Vacuum-tight, repairable nickel vapor deposition (NVD) tools created by Weber Manufacturing Technologies (Midland, Ontario, Canada) for the Boeing 787 vertical stabilizer leading edge. NVD tools are capable of long production life at high temperatures. Source: Weber Manufacturing Technologies

This tool, designed by Radius Engineering (Salt lake City, Utah) for Same-Qualified Resin Transfer Molding (SQRTM) in a project with partner COEXPAIR, was used to produce a complex main landing gear bay part with integral ribs and stringers. Source: Radius Engineering

Article From: High-Performance Composites July2011, Sara Black

ShareThis

www.carbonfiber.com.cn

Posted on: 7/1/2011

Tooling is the vital but often underappreciated silent partner behind every well-designed composite part. It also can be a very costly aspect of that part’s production. The manager for a Tier 1 aerospace facility recently revealed that the tool inventory in the plant cost more than the building and all its production equipment combined! Given that level of investment, molders want to get the most out of their tooling dollars. Toward that end, HPC compiled the following review with a focus on out-of-autoclave (OOA) approaches and other evolving technologies for thermoset composites.

Self-heating tools save time

A tooling material that has attracted considerable attention since its commercial introduction seven years ago is carbon foam. This low-density, machinable material has a low coefficient of thermal expansion (CTE) compatible with carbon composites (see “Carbon/BMI and carbon foam form Invar alternative,” under "Editor's Picks"). Now, engineers at Touchstone Research Laboratory Ltd. (Triadelphia, W.V.) have introduced Electrically Heated Tooling (EHT), a self-heated foam tool for OOA processing.

Touchstone’s Jesse Blacker explains that its CFOAM is produced from powdered bituminous coal, which is pressed into tray molds and processed under high heat and pressure in an autoclave. Foam panels are bonded together to form a near net-shape billet, which is machined to the desired shape. A tool face is formed by applying a composite material, such as Hexcel’s (Stamford, Conn.) HexTool mat material. After cure of the tool face, the CFOAM tool is CNC-machined to the final profile, wet sanded, sealed and prepared for part production.

EHT tooling incorporates a constant cross-section, resistively heated foam heating element (identical to the CFOAM used in the tool) just beneath the tool face. A graphite electrode is connected to the element to provide electricity, and the element itself is isolated from the rest of the tool mass, explains Blacker. “In this way, resistive heating occurs only beneath the tool face, making the tool more energy efficient, and the underlying foam substrate that’s not heated acts to thermally insulate the face and minimize heat losses.”

The electrical isolation of the heating element is tricky and required experimentation, he explains. Because CFOAM tools are built up from panels that are adhesively bonded together, a silver-filled conductive adhesive is needed for the panels that make up the heating element to ensure uniform current flow. The heating element is isolated by barrier layers — film adhesive, elastomeric rubber, quartz fiber or some combination of the three. “The carbon fibers used in the tool face are more conductive than the carbon foam,” Blacker points out. If fiber and foam make contact, a short circuit would result in uneven heating. “By isolating the heating element, we can create consistent tool surface heating.”

Test results show that the tool delivers mechanical properties equivalent to standard autoclave-cured laminates for both a flat and a complex tool shape.

At the recent JEC Composites Show 2011 in Paris, Techni Modul Engineering (Coudes, France) attracted interest with a self-heated tool design for high-rate production. Company CEO Serge Luquain describes the new concept, a JEC Innovation Award finalist in the Equipment category, as a “tool with a thin skin, self-heated and cooled, for curing either in or out of the autoclave.” Although few tool details were on offer, Luquain revealed that the fluid circulation system can accept oil, water or metal-based fluids and that the maximum fluid temperature is approximately 400°C/752°F. The tool skin can be made from metal or composite.

“In most cases, self-heating tools are very thick and massive,” he adds. “Ours is very thin and, thus, can heat more quickly, using less energy.” Although autoclave tools normally ramp up at 3°C to 4°C (37°F to 39°F) per minute, the self-heated tool heats at a rate of 20°C to 30°C (68°F to 86°F) per minute.

Luquain illustrates another advantage, weight savings, by contrasting the Techni Modul tool with one made of machined billets of Invar (a 36 percent nickel/steel alloy): “The Invar tool is 22 [metric] tonnes [(48,502 lb)], compared to ours at only 5 [metric] tonnes [(11,023 lb)], which is capable of making the same part more efficiently.”

The initial target market will be OOA infusion molding of large parts. Pending licensing agreements, the commercialized tool concept could soon be available in North America through a U.S. casting company, says Techni Modul. The company also is exploring resin transfer molding (RTM) tool concepts using thick 3-D stitched preforms in partnership with a Japan-based firm.

Since its debut a decade ago, Surface Generation Ltd.’s (Oakham, Rutland, U.K.) reconfigurable pin tooling (RPT) approach for OOA applications has undergone significant development, says company CEO Ben Halford. (For RPT background, see “Tooling and toolmaking innivations continue," under Editor's Picks," at top right”). “We’re now offering a fully integrated system that includes the tool, heating and cooling system, data logging, control and cure-management software, all developed in-house.” This “intelligent molding environment” works on the principle that each of the moveable pins making up the tool can be heated and cooled very accurately and rapidly. The pin temperature can rise at a rate of up to 200°C/392°F per minute to a maximum of 700°C/1292°F. The mold temperature and the temperature change rate also can be varied in localized zones. Further, the mold heating/control system can be retrofitted to a conventional tool. On an existing autoclave facesheet tool, it can accelerate heating inside the autoclave, for a cure cycle up to 20 times faster than can be achieved with the autoclave alone, claims Halford. Although the system demands considerable electrical power, energy consumption is reportedly less than 5 percent of that required by an autoclave. “And, we can put the heated tool into an autoclave and use the autoclave only to apply pressure, which creates massive energy and cycle time reductions,” adds Halford. And the company is looking to apply the temperature-control system to automated fiber placement and tape laying processes.

“Small” changes, big improvements

Nanotechnology-enhanced improvements to tooling are having a significant impact on tool durability. Featured in HPC during its development phase (see “New metal coating to optimize composite tooling,” under "Editor's Picks"), a nanostructured nickel/iron coating with a low CTE, developed by Integran Technologies Inc. (Toronto, Ontario, Canada), has been combined with carbon composite tooling prepregs from Advanced Composites Group Ltd. (ACG, Heanor, Derbyshire, U.K.) to create Carbovar. This tool concept combines the low weight and low thermal mass of a composite tool with the surface durability and hardness of a metal tool at a considerable savings, compared to all-metal tools. The winner of this year’s JEC Innovation Award in the Equipment category was a Carbovar demonstrator tool for an Airbus (Toulouse, France) A320 wing-to-fuselage fillet fairing. Reportedly, the five-year project has overcome issues that include optimizing the bond between the nanocrystalline coating and the carbon fiber tool face under thermal cycling, and achieving consistent coating thickness around complex tool face geometries. The next hurdle? Increase the tool size, currently limited to the dimensions of the metallic coating deposition tank.

Elsewhere, 3M Advanced Composites (St. Paul, Minn.) recently introduced a line of nano-enhanced epoxy resins and a line of tooling prepregs made from them, trademarked 3M Prepreg. The epoxy contains nanoscale spherical silica particles (see photo at right) at loadings of 30 to 40 percent, says Jim Nelson, 3M’s senior product development specialist: “The nanoparticles act to significantly improve resin hardness for improved scratch resistance, and they increase fracture toughness and compression strength of the composite as well, without compromising other important properties.” Tests by 3M reportedly show a 68 percent increase in Barcol hardness (79, up from 38); a 33 percent decrease in CTE (27 µm/m/°C, compared to 40 µm/m/°C in a standard epoxy); and a 24 percent decrease in moisture uptake (to only 2.7 percent).

Carbon/epoxy composites have high specific strength and stiffness but often are limited in compression strength, which is heavily influenced by the shear modulus of the matrix resin. “A higher-modulus matrix resin will support the fibers to reduce or delay microbuckling,” says Nelson, “but typically, most epoxy toughening strategies that increase matrix fracture-resistance tend to reduce the modulus.” According to the company, 3M’s spherical silica particles are extremely small (about 100 nm in diameter). Therefore, they remain homogenously distributed in the matrix, unaffected by the inadvertent filtration that could occur with larger particulate fillers as they flow through the reinforcement during wetout. In the finished part, the nanofiller helps dissipate fracture energy through viscous deformation of the matrix and increased surface roughness of the fracture plane. Says Janet Kirkman, 3M’s commercialization marketing manager, “Adding the nanosilica improves modulus and toughness while preserving glass transition temperature.”

Other benefits are said to include less moisture absorption than typical epoxies, less shrinkage during cure, a low CTE compatible with carbon parts, and decreased exotherm compared to traditional tooling prepregs. The latter makes thicker tools possible, and that means tooling laminates can be cured more quickly, saving production time.

Targeted mainly to OOA processing, the new prepregs are available in three cure temperatures: 120°F/48°C, 140°F/60°C and 180°/82°C. Although the silica at fairly high loading slightly increases the density of the prepregs, Nelson points out that overall their properties are superior to those of typical tooling prepregs. Therefore, he says, “you can work with the tool design a bit to take out some fiber and reduce the weight, if weight is a concern.” The materials are currently being tested by customers, in one case as long-term production tooling. “We’re investigating, right now, tool performance and durability after 500 cycles,” concludes Nelson.

Toolmakers refine methods, reduce costs

Tooling materials aren’t the only focus for evolution. Tool providers have led the way in combining materials and toolmaking techniques to reduce tool cost and extend the useful life of molds.

Janicki Industries (Sedro-Woolley, Wash.) offers both metal and composite tooling. The latter is offered in three classes: short two-cycle tools, intermediate 50-cycle tools and long-cycle tooling. Many are made with Janicki’s composite tooling systems, termed JAA and JRBOA, for producing tools via infusion and OOA methods. Very large tools can be fabricated using the company’s 100-ft/31m long oven, far beyond the lengths allowed by autoclaves. With the company’s gantry-mounted 5-axis machining center, which features a 100-ft bed, the cured composite tooling is machined to high tolerance. Supported by the company’s new in-house research lab, Janicki has the capability to simulate tool longevity, using thermal mass analysis, differential scanning calorimetry and heat deflection tests for customers and is working closely with resin companies to test OOA systems, adds W. Brian Holmes, Janicki’s VP, aerospace.

OOA processes, such as RTM and its variants, are maturing thanks to recent development efforts by toolmakers with expertise in metal tooling for resin infusion of complex parts. Late in 2009, for example, North Coast Tool and Mold (Cleveland, Ohio) submitted a bid for additional RTM rate tools on a very large production job. While the customer had been producing parts with tools in heated platen presses, North Coast’s president, Rich Petrovich, says his company proposed out-of-press tools, integrally heated, for faster throughput and lower energy consumption. “Our client and the end-user had to be convinced, and it was not easy,” he notes. “Our industry is justifiably concerned about using a different technology when a lot is at stake. But in the end we were able to prove that the approach worked.”

The tool design, for a part roughly 21 inches wide, 52 inches long and with a depth of 19 inches (0.5m by 1.33m by 0.49m), was produced with Invar and included heating and cooling channels, uniformly distant from the tool face. Considerable energy was saved because only the tool was heated, not large press platens. And the dedicated press for each production tool was eliminated. Because the tool heating was faster, the cycle time was reduced for more efficient throughput. The smaller tool footprint also was more ergonomic, and less handling equipment was required during the cure cycles. Adds Petrovich, “With ... projects requiring larger production quantities, more emphasis needs to be put on lower cost, lighter weight, easier-to-use tooling that doesn’t require the unnecessary expense of dedicated presses or autoclaves while saving significant energy. This translates into lower total cost for composite parts.”

Radius Engineering’s (Salt Lake City, Utah) president, Dimitrije Milovich, maintains that “high-quality, net-shaped composite parts can be produced with low void content and excellent dimensional control, with well-designed, two-part steel or aluminum tools.”

Part size, he explains, is the key when designing RTM tools. Self-clamped matched molds are acceptable for smaller parts, less than 1.5m/5 ft in length, to keep recurring labor costs lower — it takes a lot of time to fasten and unfasten all those bolts. Larger parts require considerable tool mass to react he internal resin pressure, he explains: “You may need as much as 15 tons of steel, and tool heating will be much slower and handling more difficult with a big, self-clamped tool. We generally recommend a press-clamped tool.” Although some toolmakers prefer Invar for its durability and low CTE, Milovich claims that his company has proven, in a production environment, that differences in CTE between carbon composites and aluminum can be compensated for in tool design, even in large sizes, and that hard anodizing improves aluminum’s surface durability and thermal behavior over steel and Invar, resulting in faster processes and, therefore, lower energy costs.

The company has commercialized a process called Same-Qualified Resin Transfer Molding (SQRTM), in which program-qualified, toughened prepreg is layed up in an RTM matched mold, a vacuum is drawn, air is evacuated from the layup and a small quantity of the same resin used in the prepreg is injected into the tool. This creates hydrostatic pressure on the prepreg layup that keeps volatiles and water vapor in solution and prevents void formation (see “SQRTM enables net-shape parts," under Editor's Picks”). The process reportedly yields autoclave-quality parts outside the autoclave, in a faster cure cycle. The company, in collaboration with its partner COEXPAIR (Spy, Belgium), recently designed a SQRTM tool for SABCA Limburg’s (Lummen, Belgium) complex main landing gear bay demonstrator, with integral ribs and stringers. Despite the part’s complexity, SQRTM produced a lighter, more highly integrated part faster, with fewer fasteners than an autoclaved alternative.

Another closed-molding innovator, Compose (Bellignat, France), has developed an “autonomous” self-heated RTM tool for a one-piece composite aircraft passenger door by Group Latecoere (Toulouse, France). The award-winning multipiece tool combines Invar, steel and aluminum, and accepts a complex, 3-D stitched carbon preform. Prospect Mold (Cuyahoga Falls, Ohio) specializes in multipiece RTM molds of complex geometry for highly unitized structures. Tools are designed with Unigraphics (Siemens PLM Software Inc., Plano, Texas) and CATIA (Dassault Systèmes, Lowell, Mass.), says vice-president of sales and marketing Jeff Glick. And Westminster Solutions Inc. (Plainfield, Conn.) has developed a thermal management system for RTM molding that uses circulating water rather than oil. This enables cycle time reductions of as much as 35 percent, especially during ramp-down, resulting in overall lower system cost.

Hampson Tooling Solutions, consisting of Coast Composites Inc. (Santa Ana and Irvine, Calif.), Global Tooling Systems and Odyssey Industries (Detroit, Mich.) part of U.K.-based Hampson Industries Plc, is a major supplier of metal tooling used in composites fabrication, with a long aerospace history, says Hampson CEO Paul Walsh. But, he explains, as composites have migrated into critical airframe structures over the past decade, with ever larger parts, “tooling has never before been made at the massive scale now required.”

The company has produced the tooling for more than half of the Airbus A350’s outer surface, including the forward fuselage, wings, center wingbox, and sections of mid- and aft-fuselage as well as some stringer and nacelle tools. Invar was the choice for the cure tools, with steel or aluminum selected for trim tools and other tool types. But the company also produces large composite tools. “Starting with part models, we designed and built the A350 tools from, the entire turnkey operation, which was a departure for Airbus. In the past, many of the tools were sourced locally in Europe.”

Coast is “patternless”: The digital model-based tool design is transferred directly to the shop, where Invar sheets are welded or materials are machined to form the tool face. Equipment at Coast includes large 5-axis CNC machines from Henri Liné (Granby, Quebec, Canada) and Handtmann CNC Technologies (East Dundee, Ill.) with twin Siemens Sinumerik 840D numerical controls. To ensure tight tolerances, says Walsh, Coast developed its own system to compensate for real-time temperature changes on the tool materials during machining. Accuracies reportedly can be maintained within ±0.010 inches (±0.254 mm) on tool structures up to 60 ft/6.8m long.

Waukesha Foundry Inc. (Waukesha, Wis.) has produced cast Invar custom tool components for nearly two decades, for customers that include The Boeing Co. (Chicago, Ill.), Lockheed Martin (Bethesda, Md.) and Airbus, and the company has improved its manufacturing processes to streamline production and bring down the cost of an Invar tool face. Invar is still the star in the metal tools arena due to its very low CTE, nearly the same as that of carbon/epoxy. Because an Invar mold expands and shrinks at the same rate as the composite material, no stresses are imparted to the molded composite part, says David Nelson, Waukesha’s market segment manager.

Nelson and Waukesha president Ken Kurek confirm that in many cases casting a tool skin is a better alternative to traditional bump forming and welding. Says Kurek, “With a press-shaped metal tool face that’s welded, there is always the potential for leak paths. Casting can create complex tool geometry in one piece, with no welding required.” Although metal castings also can have porosity, due to trapped gases or turbulence in the metal during the casting process, Nelson claims Waukesha’s expertise and long experience in Invar casting allows “relatively thin sheets that are vacuum tight.”

Waukesha has successfully eliminated the need for foundry patterns and the considerable cost they represent, says Nelson, by simply taking the customer-supplied CAD data for the tool face and converting it directly to the machine code that drives the company’s robotic machining centers, which produce the sand molds for the castings. Resin-bonded sand is first mixed — “There’s an entire science involved with foundry sand,” says Kurek — and dropped into a “flask” or box to contain the material while it hardens. Then the sand block is machined and trimmed to form the “cope” or upper half is mated with the “drag,” or lower half, of the mold. Molten Invar is poured into the sand mold to form the tool face or particular component. After extensive nondestructive testing, the casting is typically shipped to a tool shop for machining and assembly with a backing structure and the other hardware necessary for production.

“Our specialty is making thin cast tool facesheets,” says Nelson. “While Invar is expensive, we can make the face with less material than machining from billets, so it’s a more economical method, particularly for tools with a complex geometry.” Waukesha has supplied smaller portions of a larger tool, for instance, where a complex-shaped Invar portion is mated with and welded to a larger tool. Despite the OOA trend, Nelson and Kurek say there is always a need for robust metal molds. “Metallic tools last a lifetime,” concludes Kurek.

Tom Schmitz of Weber Manufacturing Technologies Inc. (Midland, Ontario, Canada) agrees. Weber is well known for its nickel vapor deposition (NVD) tools, made by combining ground nickel powder with carbon monoxide gas in a reactor. The resulting vapor is condensed into a liquid and pumped to a deposition chamber, where it is reheated and vaporized. Solid nickel then deposits at a thickness of 0.010 inch/0.254 mm per hour onto a CNC-machined aluminum mandrel, and forms a thin uniform shell tool face. The thickness of the nickel shell is controlled by the length of time in the chamber and can be any thickness specified, regardless of mold size. Although the CTE of NVD tools is about the same as tool steel, its thermal conductivity is three times higher for faster thermal cycling. The company produces tools for autoclave and OOA processes and can integrate conformal mold-face heating and cooling into a tool. “Out-of-autoclave hasn’t been embraced yet by aerospace manufacturers,“ Schmitz notes, “but we’re working on tools for automotive suppliers who are moving in that direction” (see, for example, “Gurit CBS for the Aston Maritn DBS,” under "Editor's Picks").

Newly approved as a Boeing vendor, Weber recently produced six NVD autoclave bonding tools for the 787 Dreamliner’s vertical tail fin leading edge. Shell thickness was about 0.20 inch/5 mm. Length ranged from 80 inches/2.03m to 130 inches/3.33m long and depth was 12 inches/0.3m to 24 inches/0.62m, with a U-shaped cross section. The backup structure is a welded steel frame.

New options for trapped tooling

Trapped tools, those used to provide support on the inside walls of hollow parts, often present part designers with the problem of postcure tool removal. Tool removal can be difficult, but leaving the tool in place can compromise part weight and function. Here, HPC reports on several new approaches to this demolding dilemma.

Smart Tooling, a trademarked product of Spintech Ventures LLC (Xenia, Ohio), uses fiber-reinforced shape memory polymers (SMPs) as a trapped tooling solution for aerospace applications and other markets. The company’s reusable Smart Mandrels and SMP Bladders are less-expensive alternatives to silicone bladders and washout materials as well as multipiece tooling that must be disassembled for removal. Further, they are quicker and easier to use, claims chief technology officer Ernie Havens. “They are also amenable to automation and faster layup processes for lower manufacturing cost,” he adds.

A Smart Mandrels blank (fiber-reinforced SMP formed into hollow tubing) is placed into a two-part mandrel mold and heated to soften the blank; when softened, the mandrel is pushed against the mold contours with air pressure. After it is cooled, the SMP becomes rigid and maintains the molded shape. The rigid mandrel is then coated with a mold release and used for layup of a composite part; the part, during cure, is heated to 250°F/121°C, which is below the mandrel’s transition temperature, says Havens. Then, the mandrel is reheated to above its softening temperature (more than 250°F). It resumes its original tube shape and can be extracted from the cured part. The company claims that layup time is significantly reduced when compared to other trapped tooling approaches, which require time to fabricate or wash out. Additionally, disposal of washout residue is not an issue.

The company’s SMP Bladder works similarly but offers compatibility with cure temperatures up to 350°F/176°C. The difference is that the layup is placed into a female tool matched to the outer mold line during cure. Air pressure is applied to the SMP Bladder for consolidation purposes. As the part heats up during cure, the SMP Bladder transitions from a rigid tool to a soft elastic tool, allowing the press operator to use air pressure to further consolidate the layup prior to cure. When the cure cycle is complete, the air pressure is vented and the SMP Bladder shrinks to its original hose-like shape and can be pulled out of the cured part like any other inflatable bladder while the composite remains in the female mold cavity to cool before final demolding.

Washout mandrels have been a traditional choice, but Advanced Ceramics Mfg. (Tucson, Ariz.) says it has taken them to the next level, with its RapidCore mandrel manufacturing process, which eliminates mandrel tooling. A mandrel is “printed” directly from the customer’s CAD file, using an additive manufacturing process (see “The rise of rapid manufacturing,” under "Editor's Picks," at top right) and material system, based on the company’s water-soluble materials. When it is complete, the mandrel is coated with a fluoropolymer tape to protect it from water and is then used for part layup. Mandrels can be created in a fraction of the time required for plaster or eutectic salts and possess a compressive strength greater than 100 psi/6.89 bar and a thermal degradation temperature of approximately 350°F/177°C, which is consistent with industry-standard autoclave parameters. After part cure, the RapidCore material is simply washed out with water.

Nevada Composites (Dayton, Nevada) provides warm-water washout mandrels for trapped tooling and traditional single-sided tools, using a moderately priced rapid tooling material, trademarked Green-Aero, based on ceramic microspheres mixed with water-soluble inorganic binders. Lightweight tools are produced via a vacuum molding process in a few days, a process that is speeded by making molds for the mandrels and masters for single-sided tools using an additive manufacturing process, fused deposition modeling. The mandrels and tools have a low CTE and low thermal mass, says company CEO Linda Clements. “By tailoring the tooling material by, for example, varying the particle type and amount or the binder quantity and additives, we can adjust washout properties, improve machinability and mechanical properties, and tailor thermal properties.” Green-Aero is reportedly environmentally benign.