Carbon Fiber Garden Series Part - 碳纤维花园设计

By Carbonfiber.com.cn

This post was guest blogged by Brett Levine of False Profit Labs. To learn more about the carbon fiber garden product, visit the False Profit Labs blog, follow them on Twitter, and check out their Facebook page. This is part 2 in our carbon fiber garden series, you can read part 1 here.

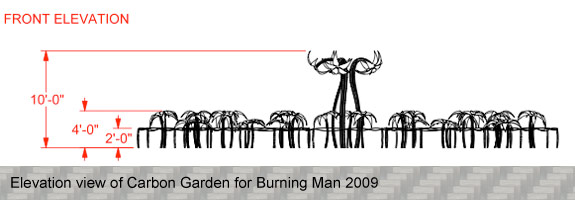

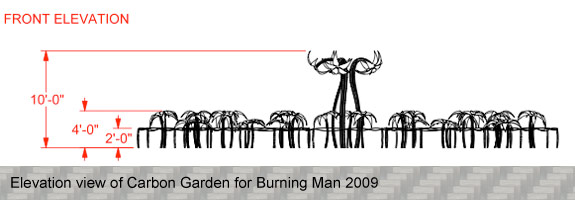

The False Profit Labs motto is better art through science–we are a group of art engineers who build larger-than-life interactive fire sculptures. Our project is called Carbon Garden: Forty flowers, up to ten feet tall, made from carbon fiber, that shoot three-foot-long flames from their blooms, with interactive fire behaviors that react to people around them. I’m Brett Levine, the project lead, here to share a few tales about the process of making our sculpture, some insights into working with magical carbon fiber material, and how to reveal its natural beauty.

Back in March, when we started building things out of carbon fiber, we first made a flat sheet, then went on to curvy pieces, following all the advice from the experts out there. We made fiberglass molds, applied layers of mylar, sprayed highly effective (and expensive) mold release so our parts wouldn’t stick to our molds, even investigated vacuum bagging and oven curing. And yes, we made a few shapes that resembled something like leaves. They were made out of carbon fiber, so of course they were incredibly strong and lightweight. The shapes weren’t quite the flower petals we were aiming for, but it seemed just around the corner that we would bend this exotic black weave to our will and into whatever shape we could imagine.

As with most art (and science) things didn’t quite go as planned. In fact, to lay up carbon fiber into the kinds of organic shapes that actually look like the natural flowers we had envisioned, compound curves (curves that bend around more than one axis) are required. The nature of 282 plain weave, a type of carbon fiber that has a beautiful regular grain, doesn’t lend itself to stretching into these complicated three dimensional shapes. Instead of pursuing ever more complicated fabrication techniques that are common in industry, we kept to a mantra of “set the carbon fiber free.” Instead of forcing the medium into our mold (both figuratively and literally) we allowed it to flow and stretch and twist in the shapes it fell into most naturally. The carbon fiber production approach was totally unconventional, and the results were stunning.

Our first successful flower that looks natural, and has that perfect shiny carbon fiber grain, was laid up over a carnuba waxed beach ball! By draping the wetted fabric, and stretching, sculpting and folding it over the ball (not to mention playing around with sticky gloves quite a bit), we emphasize the flowing folds that carbon fiber fabric holds so beautifully.

Now it’s not quite as simple as just setting the fabric on a beach ball. There were a few tricks of the trade we learned in fits and starts, with many (costly) trials and errors. I’ll share a few of them here, and if you ever attempt to build your own parts, perhaps you can choose between the standard techniques you’ll find in industry and some of our homegrown methods.

First lesson: One layer at a time. Look around at anything made of carbon fiber. How many sides does it have? One I bet! That is, almost every application of carbon fiber only has one exposed side. From bicycle forks and frames, to coffee tables and car wheels, you only see a single exposed side of carbon fiber. The other side is ugly as hell! But you don’t see it. In our flowers, you do see it, and that creates a great challenge to achieve the shiny matte finish we love on both sides. The answer is to wet one layer at a time, let it cure, apply another layer inside, perhaps with some foam core or folded sheets for extra strength. Whatever parts of the carbon fiber touch the mold will most likely have a dull, ugly finish. But we can later add epoxy or additional layers to give these parts a perfect finish.

Second lesson: Blush-free epoxy. By switching to System 3 Silvertip blush free epoxy, we can cure without any mylar or peel ply in plain air and get a great finish. Nice epoxy.

Third lesson: Saran wrap. In fact any crystalline plastic (food products require this) as opposed to amorphous plastic (like ABS) works great as a mold release. So we saved some serious cash giving up on expensive release agents, vacuum bagging film and peel ply, in favor of simple stuff from the kitchen cabinet.

Fourth lesson: No molds! The problem when making sculptures with carbon fiber is that when wetted with epoxy it collapses under its own weight. For example if you want to make a sculpture of a person, you need some structure to hold it in that shape for 8-12 hours while it cures. We learned to lay up individual sections of the fabric, while other dry parts (which are much sturdier) support themselves. Once cured, the solid carbon fiber parts act as their own molds to hold up the rest, which we then slather with epoxy. This allowed us to make interesting flower shapes like calla lilies. Getting even further out there, we unweave the carbon fiber fabric and use the threads to make grass panels. With a ShopBot CNC Router and a diamond end mill we cut lettering for carbon fiber signage and for geometric petals.

We are combining carbon fiber with other more common materials such as hammered and bent steel stems, copper and brass wire leaves, and of course digitally programmable flame effects. Well, flame effects may not be that common in general, but they are common in False Profit Labs artwork. The problem when shooting fire out of a carbon fiber sculpture is that carbon fiber lights on fire! Technically though it’s not the carbon fiber that ignites, but the epoxy, that sticky resin that turns the fabric into a sturdy composite. Our solution: no epoxy. We mount our flame effect in a biaxial twill carbon fiber sleeve and wet out (add epoxy) only the portion of the tube away from the fire. The epoxy-free sleeve end frays into a pleasing stranded cone which the fire will not damage.

Overall, getting to know the idiosyncrasies of carbon fiber has been quite a trying process, in some ways made more difficult by our unusual fabrication goals. Yet, like any new artistic medium, you have to live and breathe it, speak its language, play with it until you can visualize with great accuracy what it will do in situations you haven’t quite tried. The payout with carbon fiber is, well I don’t have to tell you all how great carbon fiber is–that patterned sheen that tricks your eyes with swirling moirees in the sunlight, the depth of its blackness, its strength and its lightness. I have come to love this material and hope some of you will get to enjoy our Carbon Garden this summer.

False Profit Labs will debut Carbon Garden July 11 at the Sand by the Ton party at American Steel in Oakland, CA. Next, Carbon Garden will appear at Fire Arts Festival, also in Oakland July 15-18. Then Carbon Garden in its full form will run nightly at Burning Man in the Black Rock Desert, NV the week of August 31.

This post was guest blogged by Brett Levine of False Profit Labs. To learn more about the carbon fiber garden product, visit the False Profit Labs blog, follow them on Twitter, and check out their Facebook page. This is part 2 in our carbon fiber garden series, you can read part 1 here.

The False Profit Labs motto is better art through science–we are a group of art engineers who build larger-than-life interactive fire sculptures. Our project is called Carbon Garden: Forty flowers, up to ten feet tall, made from carbon fiber, that shoot three-foot-long flames from their blooms, with interactive fire behaviors that react to people around them. I’m Brett Levine, the project lead, here to share a few tales about the process of making our sculpture, some insights into working with magical carbon fiber material, and how to reveal its natural beauty.

Back in March, when we started building things out of carbon fiber, we first made a flat sheet, then went on to curvy pieces, following all the advice from the experts out there. We made fiberglass molds, applied layers of mylar, sprayed highly effective (and expensive) mold release so our parts wouldn’t stick to our molds, even investigated vacuum bagging and oven curing. And yes, we made a few shapes that resembled something like leaves. They were made out of carbon fiber, so of course they were incredibly strong and lightweight. The shapes weren’t quite the flower petals we were aiming for, but it seemed just around the corner that we would bend this exotic black weave to our will and into whatever shape we could imagine.

As with most art (and science) things didn’t quite go as planned. In fact, to lay up carbon fiber into the kinds of organic shapes that actually look like the natural flowers we had envisioned, compound curves (curves that bend around more than one axis) are required. The nature of 282 plain weave, a type of carbon fiber that has a beautiful regular grain, doesn’t lend itself to stretching into these complicated three dimensional shapes. Instead of pursuing ever more complicated fabrication techniques that are common in industry, we kept to a mantra of “set the carbon fiber free.” Instead of forcing the medium into our mold (both figuratively and literally) we allowed it to flow and stretch and twist in the shapes it fell into most naturally. The carbon fiber production approach was totally unconventional, and the results were stunning.

Our first successful flower that looks natural, and has that perfect shiny carbon fiber grain, was laid up over a carnuba waxed beach ball! By draping the wetted fabric, and stretching, sculpting and folding it over the ball (not to mention playing around with sticky gloves quite a bit), we emphasize the flowing folds that carbon fiber fabric holds so beautifully.

Now it’s not quite as simple as just setting the fabric on a beach ball. There were a few tricks of the trade we learned in fits and starts, with many (costly) trials and errors. I’ll share a few of them here, and if you ever attempt to build your own parts, perhaps you can choose between the standard techniques you’ll find in industry and some of our homegrown methods.

First lesson: One layer at a time. Look around at anything made of carbon fiber. How many sides does it have? One I bet! That is, almost every application of carbon fiber only has one exposed side. From bicycle forks and frames, to coffee tables and car wheels, you only see a single exposed side of carbon fiber. The other side is ugly as hell! But you don’t see it. In our flowers, you do see it, and that creates a great challenge to achieve the shiny matte finish we love on both sides. The answer is to wet one layer at a time, let it cure, apply another layer inside, perhaps with some foam core or folded sheets for extra strength. Whatever parts of the carbon fiber touch the mold will most likely have a dull, ugly finish. But we can later add epoxy or additional layers to give these parts a perfect finish.

Second lesson: Blush-free epoxy. By switching to System 3 Silvertip blush free epoxy, we can cure without any mylar or peel ply in plain air and get a great finish. Nice epoxy.

Third lesson: Saran wrap. In fact any crystalline plastic (food products require this) as opposed to amorphous plastic (like ABS) works great as a mold release. So we saved some serious cash giving up on expensive release agents, vacuum bagging film and peel ply, in favor of simple stuff from the kitchen cabinet.

Fourth lesson: No molds! The problem when making sculptures with carbon fiber is that when wetted with epoxy it collapses under its own weight. For example if you want to make a sculpture of a person, you need some structure to hold it in that shape for 8-12 hours while it cures. We learned to lay up individual sections of the fabric, while other dry parts (which are much sturdier) support themselves. Once cured, the solid carbon fiber parts act as their own molds to hold up the rest, which we then slather with epoxy. This allowed us to make interesting flower shapes like calla lilies. Getting even further out there, we unweave the carbon fiber fabric and use the threads to make grass panels. With a ShopBot CNC Router and a diamond end mill we cut lettering for carbon fiber signage and for geometric petals.

We are combining carbon fiber with other more common materials such as hammered and bent steel stems, copper and brass wire leaves, and of course digitally programmable flame effects. Well, flame effects may not be that common in general, but they are common in False Profit Labs artwork. The problem when shooting fire out of a carbon fiber sculpture is that carbon fiber lights on fire! Technically though it’s not the carbon fiber that ignites, but the epoxy, that sticky resin that turns the fabric into a sturdy composite. Our solution: no epoxy. We mount our flame effect in a biaxial twill carbon fiber sleeve and wet out (add epoxy) only the portion of the tube away from the fire. The epoxy-free sleeve end frays into a pleasing stranded cone which the fire will not damage.

Overall, getting to know the idiosyncrasies of carbon fiber has been quite a trying process, in some ways made more difficult by our unusual fabrication goals. Yet, like any new artistic medium, you have to live and breathe it, speak its language, play with it until you can visualize with great accuracy what it will do in situations you haven’t quite tried. The payout with carbon fiber is, well I don’t have to tell you all how great carbon fiber is–that patterned sheen that tricks your eyes with swirling moirees in the sunlight, the depth of its blackness, its strength and its lightness. I have come to love this material and hope some of you will get to enjoy our Carbon Garden this summer.

False Profit Labs will debut Carbon Garden July 11 at the Sand by the Ton party at American Steel in Oakland, CA. Next, Carbon Garden will appear at Fire Arts Festival, also in Oakland July 15-18. Then Carbon Garden in its full form will run nightly at Burning Man in the Black Rock Desert, NV the week of August 31.